| Line 40: | Line 40: | ||

<p>In order to characterize the expression system, we first acquired the experiment data of | <p>In order to characterize the expression system, we first acquired the experiment data of | ||

GFP production rate per cell (RFU per Abs per min) under different | GFP production rate per cell (RFU per Abs per min) under different | ||

| − | concentration of inducers <img src="/wiki/images/1/12/T--BNDS_CHINA--model002.gif" /> (M) (see <a href=" | + | concentration of inducers <img src="/wiki/images/1/12/T--BNDS_CHINA--model002.gif" /> (M) (see <a href="/Team:BNDS_CHINA/Experiments">experiment</a>). Then the experimental |

data were fitted using the Hill equation:</p> | data were fitted using the Hill equation:</p> | ||

<div align="center" width="90%"> | <div align="center" width="90%"> | ||

| Line 57: | Line 57: | ||

(<img width="22" height="21" src="/wiki/images/9/98/T--BNDS_CHINA--model009.png"/>). The four parameters | (<img width="22" height="21" src="/wiki/images/9/98/T--BNDS_CHINA--model009.png"/>). The four parameters | ||

(<img width="11" height="12" src="/wiki/images/0/0f/T--BNDS_CHINA--model011.png" />, | (<img width="11" height="12" src="/wiki/images/0/0f/T--BNDS_CHINA--model011.png" />, | ||

| − | <img width="11" height="12" src=" | + | <img width="11" height="12" src="/wiki/images/5/57/T--BNDS_CHINA--model013.png" />, |

| − | <img width="11" height="12" src=" | + | <img width="11" height="12" src="/wiki/images/9/9f/T--BNDS_CHINA--model015.png"/>, |

| − | <img width="11" height="12" src=" | + | <img width="11" height="12" src="/wiki/images/0/0d/T--BNDS_CHINA--model017.png"/> |

) were estimated to obtain the best fit curve by performing a | ) were estimated to obtain the best fit curve by performing a | ||

non-linear curve fitting using the experimental data. Among the parameters, n | non-linear curve fitting using the experimental data. Among the parameters, n | ||

| Line 69: | Line 69: | ||

<div align=center> | <div align=center> | ||

| − | <img width="80%" src=" | + | <img width="80%" src="/wiki/images/0/06/T--BNDS_CHINA--model018.png"/> |

<br/>Fig 1. Characterization of Sensor Device I (BBa_K2548000 + BBa_K2548003)</div> | <br/>Fig 1. Characterization of Sensor Device I (BBa_K2548000 + BBa_K2548003)</div> | ||

<p>The figure above shows the modelling result of Device I. The derived equation is:</p> | <p>The figure above shows the modelling result of Device I. The derived equation is:</p> | ||

| − | <div align=center><img width="186" height="31" src=" | + | <div align=center><img width="186" height="31" src="/wiki/images/4/45/T--BNDS_CHINA--model020.png"/></div> |

<p>And the correlation coefficient of the equation is 0.9816. </p> | <p>And the correlation coefficient of the equation is 0.9816. </p> | ||

| − | <div align=center><img width="80%" src=" | + | <div align=center><img width="80%" src="/wiki/images/a/a8/T--BNDS_CHINA--model060.png"/> |

<br/>Fig 2. Characterization of Sensor Device II (BBa_K2548001 + BBa_K2548003)</div> | <br/>Fig 2. Characterization of Sensor Device II (BBa_K2548001 + BBa_K2548003)</div> | ||

<p>The figure above shows the modelling result of Device I. The derived equation is:</p> | <p>The figure above shows the modelling result of Device I. The derived equation is:</p> | ||

| − | <div align=center><img width="187" height="31" src=" | + | <div align=center><img width="187" height="31" src="/wiki/images/1/18/T--BNDS_CHINA--model023.png"/></div> |

<p>And the correlation coefficient of the equation is 0.9952. </p> | <p>And the correlation coefficient of the equation is 0.9952. </p> | ||

<p>We used the two equations to predict the efficiency of the sensor devices. See the analysis of | <p>We used the two equations to predict the efficiency of the sensor devices. See the analysis of | ||

| − | these results at <a href=" | + | these results at <a href="/Team:BNDS_CHINA/Demonstrate">demonstrate</a></p> |

<h2>V. Visualization of Data in Three-Dimensions</h2> | <h2>V. Visualization of Data in Three-Dimensions</h2> | ||

| Line 94: | Line 94: | ||

systematic and experimental errors. The three axes are named respectively as | systematic and experimental errors. The three axes are named respectively as | ||

Time (min), | Time (min), | ||

| − | <img width="48" height="14" src=" | + | <img width="48" height="14" src="/wiki/images/3/36/T--BNDS_CHINA--model024.png"/>, and GFP |

production rate. The three variables are defined respectively in different | production rate. The three variables are defined respectively in different | ||

sets, automatically imported from Excel to maintain the efficiency and | sets, automatically imported from Excel to maintain the efficiency and | ||

| Line 102: | Line 102: | ||

<p> C4-HSL concentration ( M ) ∈ [ | <p> C4-HSL concentration ( M ) ∈ [ | ||

| − | <img width="25" height="14" src=" | + | <img width="25" height="14" src="/wiki/images/e/e5/T--BNDS_CHINA--model025.png" /> , |

| − | <img width="32" height="14" src=" | + | <img width="32" height="14" src="/wiki/images/9/9b/T--BNDS_CHINA--model026.png" /> ] for geometric |

sequence of ratio of 5 . To maintain the integrity of image, the value of | sequence of ratio of 5 . To maintain the integrity of image, the value of | ||

concentration is replaced by marks from 1-15. </p> | concentration is replaced by marks from 1-15. </p> | ||

| Line 118: | Line 118: | ||

different views.</p> | different views.</p> | ||

| − | <div align=center><img width="80%" src=" | + | <div align=center><img width="80%" src="/wiki/images/8/80/T--BNDS_CHINA--model027.png"/> |

<br/>Fig 3. Visualization of Sensor Device I Experiment Data</div> | <br/>Fig 3. Visualization of Sensor Device I Experiment Data</div> | ||

| − | <div align=center><img width="80%" src=" | + | <div align=center><img width="80%" src="/wiki/images/5/54/T--BNDS_CHINA--model029.png"/> |

<br/>Fig 4. Visualization of Sensor Device II Experiment Data</div> | <br/>Fig 4. Visualization of Sensor Device II Experiment Data</div> | ||

| Line 129: | Line 129: | ||

Function. </p> | Function. </p> | ||

| − | <div align=center><img width="70%" src=" | + | <div align=center><img width="70%" src="/wiki/images/f/f2/T--BNDS_CHINA--model031.png"/> |

<br/>Fig 5. Visualization of Sensor Device I Experiment Data in Plane</div> | <br/>Fig 5. Visualization of Sensor Device I Experiment Data in Plane</div> | ||

| − | <div align=center><img width="70%" src=" | + | <div align=center><img width="70%" src="/wiki/images/3/39/T--BNDS_CHINA--model033.png"/> |

<br/>Fig 5. Visualization of Sensor Device II Experiment Data in Plane</div> | <br/>Fig 5. Visualization of Sensor Device II Experiment Data in Plane</div> | ||

Revision as of 02:03, 16 October 2018

Model

I. Summary

Our model helped us to optimize the A. hydrophila sensor devices. At first, we measured the concentration of C4-HSL in A. hydrophila culture by using mass spectrum. Then, we tested the GFP production rate of sensor device I. The experimental results were characterized by using Hill equation, which modelled the GFP synthesis rate as a function of input concentration of the inducer, C4-HSL. However, when we predicted the efficiency of this device in real environment by the derived function, we found the fluorescence was too low to be detected. Therefore, we adjusted our design by increasing rhlR RBS strength and modelled the experimental results by using Hill equation again. This time, we found the device’s (BBa_K2548001) fluorescence in real environment was enough to be detected. More importantly, our model can help to indicate the A. hydrophila concentration in different environments, and alerts the aquaculture managers the danger of pathogen infection. In addition, we visualize the data in three-dimensions to show how GFP production rate per cell over time at different C4-HSL inducer concentrations to characterize the sensor in a more comprehensive way.

II. Assumptions

- When the concentration of changes, the synthesis rate of GFP increases, and its fluorescence increases.

- GFP synthesis rate is only affected by the concentration of C4-HSL, and the relationship can be simplified into a non-linear function (Hill equation).

- The function of relevant proteins is assumed stable throughout the experiment.

- The difference between individual subtype of bacteria is omitted.

III. Design of Characterizations

In order to characterize the expression system, we first acquired the experiment data of

GFP production rate per cell (RFU per Abs per min) under different

concentration of inducers  (M) (see experiment). Then the experimental

data were fitted using the Hill equation:

(M) (see experiment). Then the experimental

data were fitted using the Hill equation:

In biochemistry, the binding ability of a ligand to a macromolecule is often increased if other ligands have already present on the same macromolecule. The hill equation is used to determine the cooperativeness of a ligand binding to its receptor, and it can describe the relationship between the expression level of genes which are regulated and the quantity of regulatory factors.

We model the GFP synthesis rate

(![]() ) as a function of input concentration of

) as a function of input concentration of

![]() (

(![]() ). The four parameters

(

). The four parameters

(![]() ,

,

![]() ,

,

![]() ,

,

![]() ) were estimated to obtain the best fit curve by performing a

non-linear curve fitting using the experimental data. Among the parameters, n

is the Hill coefficient, which describes the cooperativity; C is the

concentration of C4-HSL (M) which produces half occupation. This curve fitting was performed using Logger Pro. (Saeidi et

al, 2011).

) were estimated to obtain the best fit curve by performing a

non-linear curve fitting using the experimental data. Among the parameters, n

is the Hill coefficient, which describes the cooperativity; C is the

concentration of C4-HSL (M) which produces half occupation. This curve fitting was performed using Logger Pro. (Saeidi et

al, 2011).

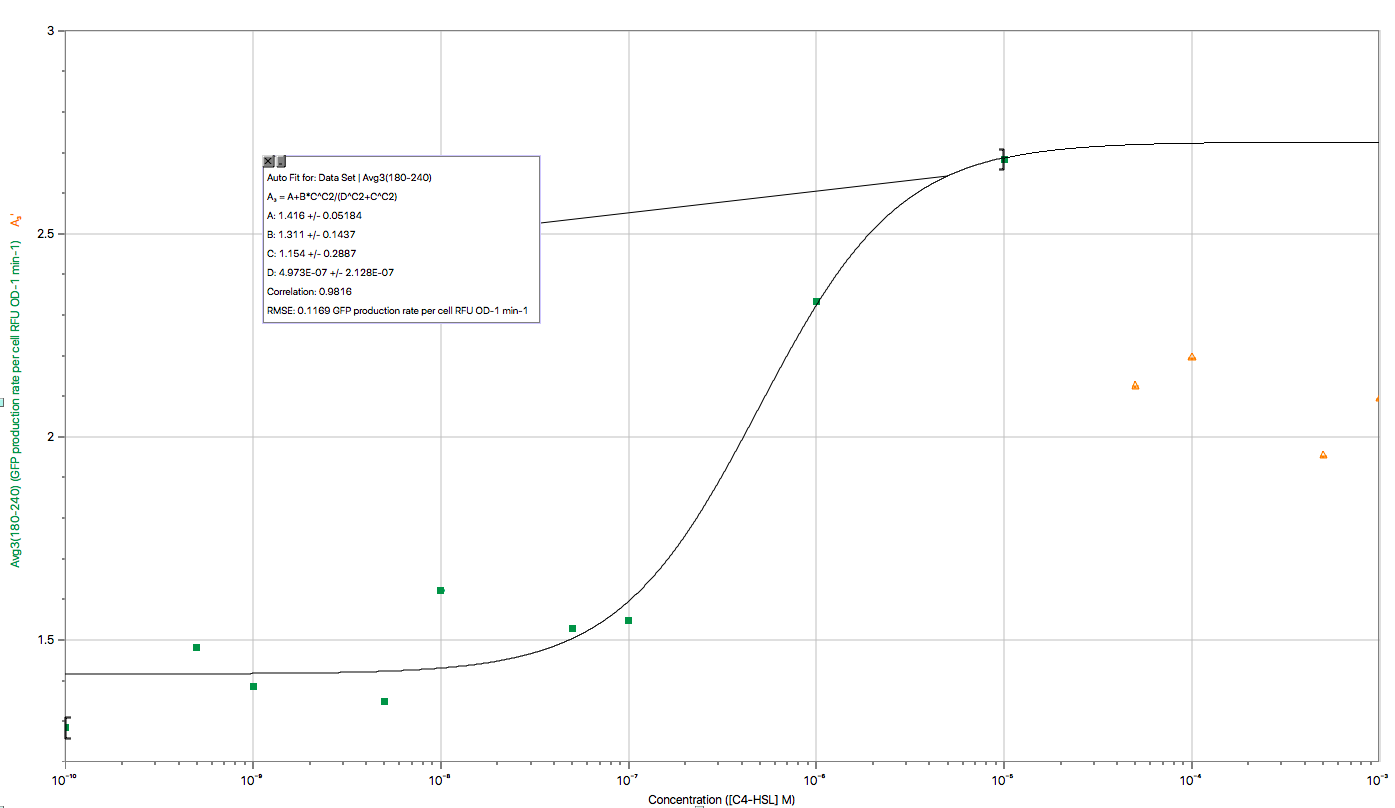

IV. Results of Characterizations of Sensor Device I and Device II

Fig 1. Characterization of Sensor Device I (BBa_K2548000 + BBa_K2548003)

The figure above shows the modelling result of Device I. The derived equation is:

And the correlation coefficient of the equation is 0.9816.

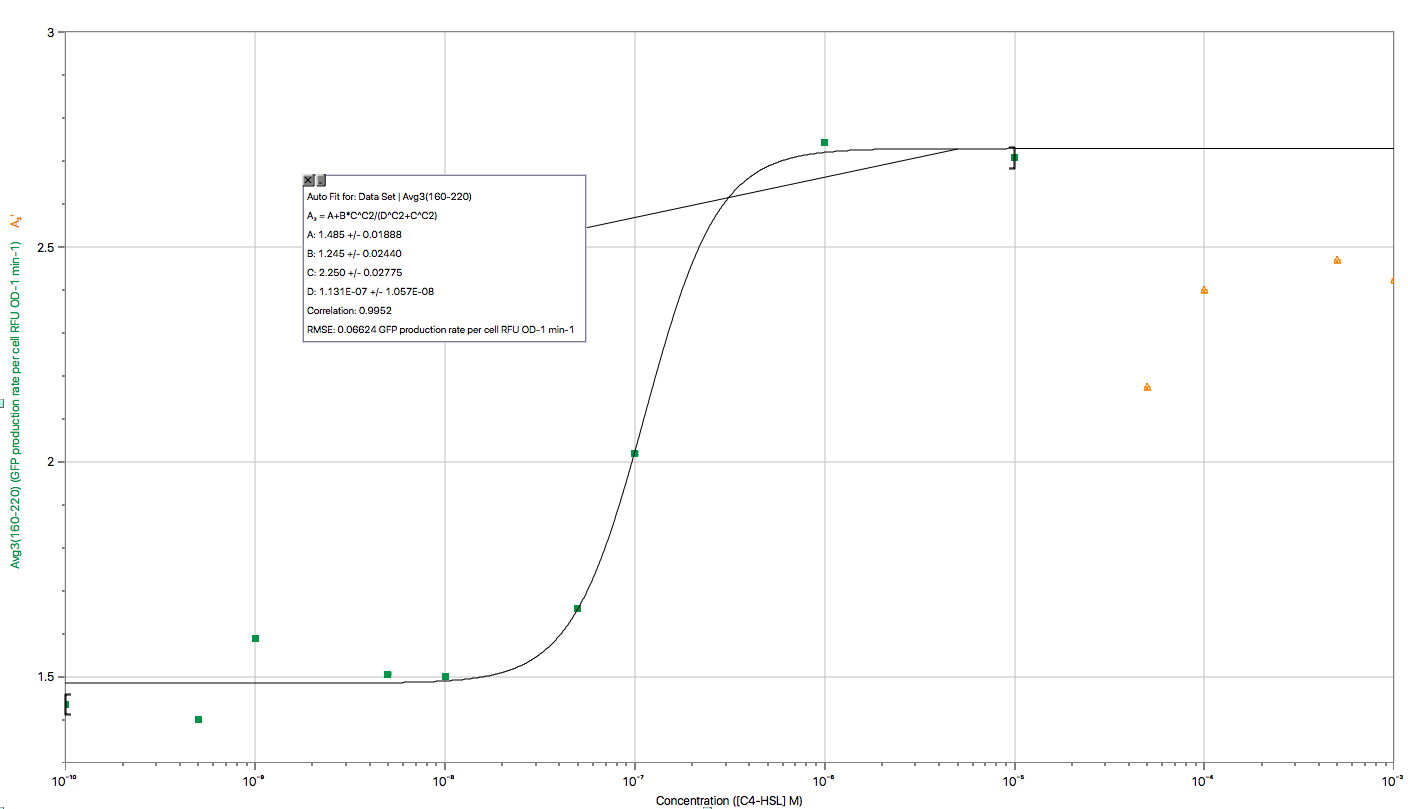

Fig 2. Characterization of Sensor Device II (BBa_K2548001 + BBa_K2548003)

The figure above shows the modelling result of Device I. The derived equation is:

And the correlation coefficient of the equation is 0.9952.

We used the two equations to predict the efficiency of the sensor devices. See the analysis of these results at demonstrate

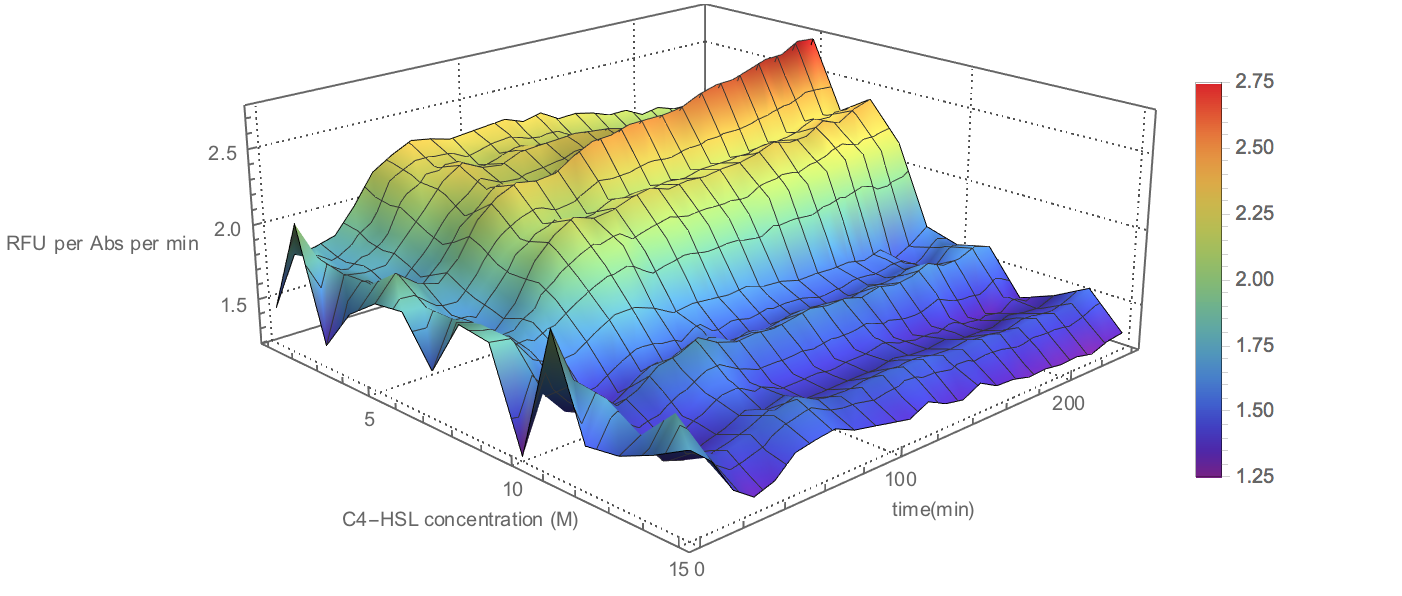

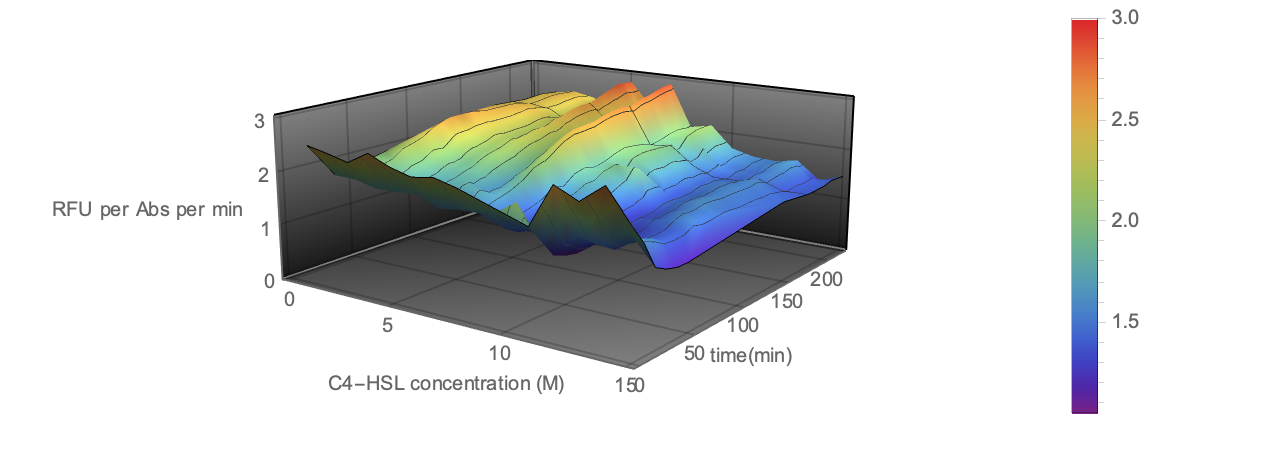

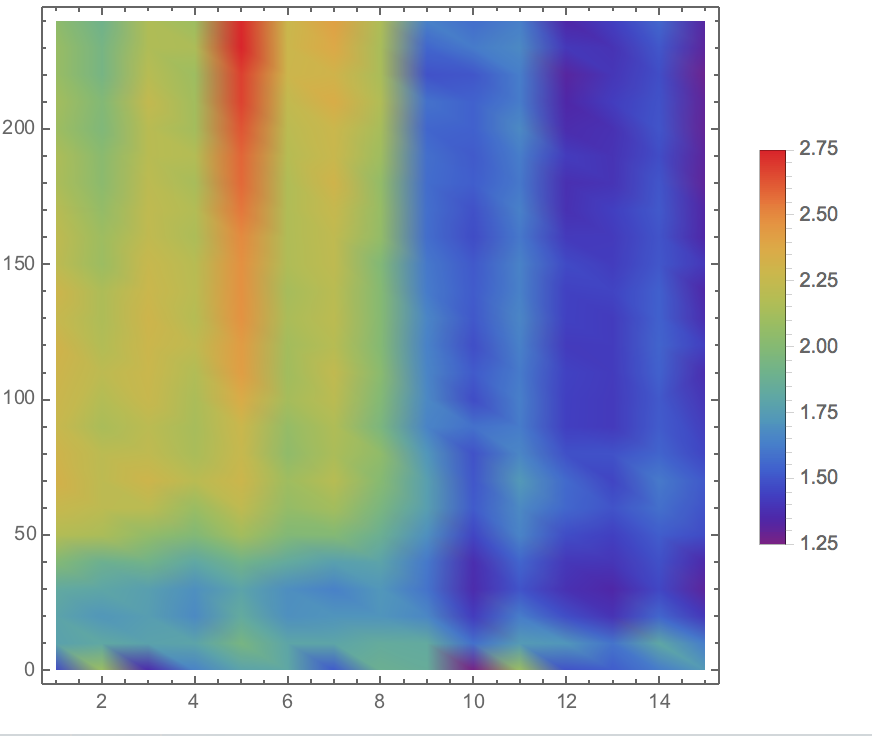

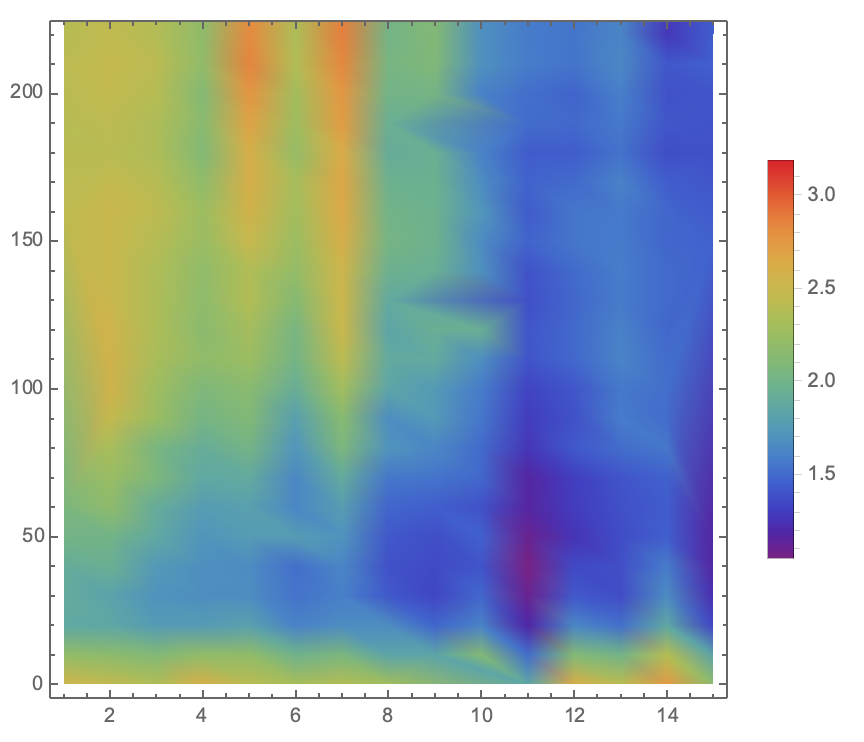

V. Visualization of Data in Three-Dimensions

The GFP production rate is converted as RFU per Abs per min,

calculated through the arithmetic average of three trails to eliminate the

systematic and experimental errors. The three axes are named respectively as

Time (min),

![]() , and GFP

production rate. The three variables are defined respectively in different

sets, automatically imported from Excel to maintain the efficiency and

productivity of modeling.

, and GFP

production rate. The three variables are defined respectively in different

sets, automatically imported from Excel to maintain the efficiency and

productivity of modeling.

Time( t ) ∈ [ 0,220 ] with interval of 10mins .

C4-HSL concentration ( M ) ∈ [

![]() ,

,

![]() ] for geometric

sequence of ratio of 5 . To maintain the integrity of image, the value of

concentration is replaced by marks from 1-15.

] for geometric

sequence of ratio of 5 . To maintain the integrity of image, the value of

concentration is replaced by marks from 1-15.

GFP production rate ∈ [ 0,4 ] from experimental test experience.

The modeling is achieved through Mathematica 11. All discrete points are contained in manual data set. To show the variation tendency of data, we took MeshFunction to connect the adjacent points and present the regional changing trend, like the concavity or convexity. To specify and highlight the progressive changes of GFP production rate, we took the PlotLegends Function of Colorful pattern. The three-dimension graph can be rotated 360 degrees and observed from different views.

Fig 3. Visualization of Sensor Device I Experiment Data

Fig 4. Visualization of Sensor Device II Experiment Data

To illustrate the three-dimensional data in plane and the height ( z -axis value) is represented through the shade of color. The image is generated through ListDensityPlot Function.

Fig 5. Visualization of Sensor Device I Experiment Data in Plane

Fig 5. Visualization of Sensor Device II Experiment Data in Plane

References

Saeidi, N., Wong, C. K., Lo, T., Nguyen, H. X., Ling, H., Leong, S. S., . . . Chang, M. W. (2014). Engineering microbes to sense and eradicate Pseudomonas aeruginosa, a human pathogen. Molecular Systems Biology, 7(1), 521-521. doi:10.1038/msb.2011.55